About TJCC

Introduction of TJCC (UTokyo-JAXA Center for Composites)

Director of TJCC, Professor

Nobuo Takeda

Currently, almost 70 % of commercial carbon fibers are made in Japan, and Japanese aerospace industries are leading in designing, manufacturing and processing of CFRP structures for aerospace applications. For example, recent on-going development of MRJ, Japanese small-sized commercial aircraft, relies on CFRP structures for its high performance. In addition, almost 35 % of Boeing 787 structures are being made by Japanese industries which are mostly made with CFRP. However, USA and European governments are beginning to invest much fund to promote industry-academia collaboration programs on advanced composite structures because of its importance in near future. Asian countries including China are also emphasizing the significance of carbon fibers and composites to catch up our technology.

Our technological advantage has been established by Japanese industries mainly through their own efforts. But people begin to notice that more inclusive all-Japan industry-academia collaboration efforts are necessary to distinguish our CFRP manufacturing technology and high performance from other countries.

Then, we decided to establish TJCC to play such a key role by combining both human and equipment resources of the Department of Advanced Energy, Graduated School of Frontier Sciences, the University of Tokyo, and the Composite Research Group of JAXA (Japan Aerospace Exploitation Agency). Both research groups are recognized as world-class research teams in advanced composites with strong academic backgrounds, and TJCC can be an excellent focal point of Japanese industry-academia collaboration. Research themes can be selected based on the matching between the seeds and needs of our participating members through the industry-academia network on advanced composites. TJCC accepts active faculty members of other universities and researchers from industries as associate collaboration members to form an all-Japan research team.

The following three research targets are being pursued:

- To develop novel composite systems for future industries,

- To develop intelligent and low-cost manufacturing/processing methods, and

- To expand the applications of advanced composites for long life and low carbon emission.

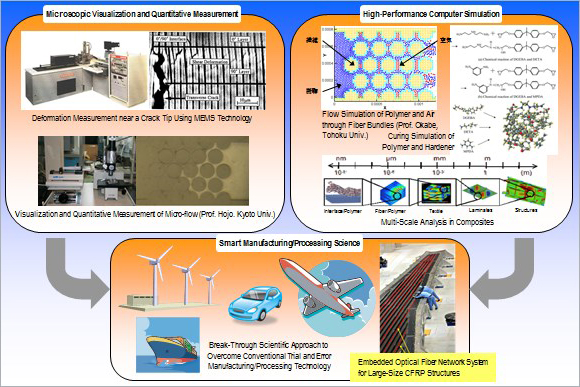

Our academic advantage on advanced visualization techniques (including optical fiber sensor network system) and multi-scale computer simulation methodology are fully utilized to develop the “smart manufacturing/processing science” to overcome conventional trial and error manufacturing routes (Fig. 1). We believe these approaches can establish strong bases to strengthen our aerospace industries and to realize the safe and sound society with low carbon emission.

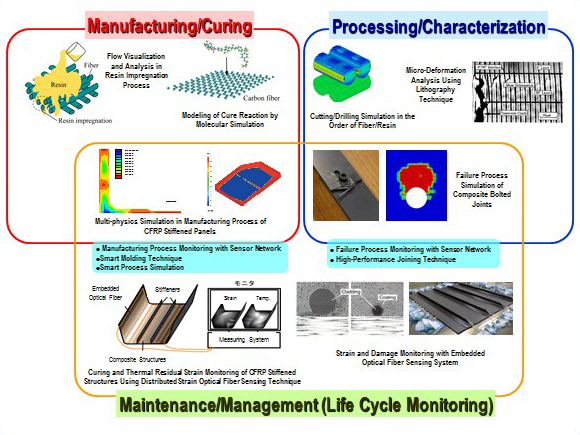

The following research themes (Fig. 2) are currently under way: (1) Manufacturing/Curing, (2)Processing/Characterization, and (3)Maintenance/Management (Life Cycle Monitoring).

(including optical fiber sensor network system) and multi-scale computer simulation methodology.

(1) Manufacturing/Curing, (2) Processing/Characterization, and (3) Maintenance/Management (Life Cycle Monitoring).